About Huckleberry Railroad

It has been said that the Huckleberry Railroad got its name because the train ran so slowly that passengers could easily jump off, pick some huckleberries and jump back on again. Part of the Flint Pere Marquette Railroad, it began operating in 1857.

The train operates with coal-powered, steam engine locomotives. It currently pulls eight coaches, each numbered and each with its own story. The caboose serves several functions and is where the conductor sits during the train runs.

There are several railroad events scheduled throughout the year: Halloween at Crossroads, Christmas at Crossroads, Railfans Weekend and A Day Out With Thomas™.

During the summer, the train runs three times a day Thursday through Sunday – noon, 2pm and 4pm. The 40-minute ride travels nine miles of track and currently, the train can carry 350 passengers.

The Conductors

Incredibly cheerful, friendly and knowledgeable, the Huckleberry Railroad Conductors love what they do. Head Conductor Bill Cesaro is often seen playing his ukulele around the Village to entertain visitors. He has been employed there for 23 years, and says he has worked in every building at Crossroads. He previously worked in the model train department at Rider’s Hobby Shop in Flint. “I came out here to do the real thing,” he says with a smile. “My strength is all of these guys (his fellow conductors). Without them, this would be nothing – like a balloon without air.”

Bill Cesaro

“We get to meet all kinds of people and teach them history without them even knowing it!”

– Bill Cesaro

Lewie Young, second in command, has been a conductor for the last 18 years and says his duties are very important. “The conductor is in charge of the train,” he explains. “He has control of the train and tells the engineer where to go and when to stop.”

Ken Lewis, who is third in command, has been a conductor since 1970, after working as a conductor for various other railroads. “Handsome Harry,” now retired, was a conductor for 15 years and the most popular, most-requested conductor, according to Cesaro. Now that Harry has retired, Cesaro says Lewie is the most popular. “Everyone loves Lewie and he’s everybody’s friend. We call Larry Coleman ‘Hollywood’ because he always looks good and likes to be on camera.

“We are also an entertainment company,” Cesaro points out. “We are actors and just don’t know it. We are the supporting cast and the train is the star of

the show.”

What’s the best thing about being a Huckleberry Railroad conductor? “It’s the people,” Cesaro says. “We get to meet all kinds of people and teach them history without them even knowing it!”

Note: Conductors serve double-duty, working as janitors, making sure the coaches are swept and cleaned after each run.

(L-R) The dedicated train crew includes Daniel Worthy, Zach Hebel, Logan Jordan, Mick Kimball and Larry Coleman.

“It is a lot of work and there is a lot to it.”

– John Hewlett

Railroad Consultant

Getting the Train Ready

Getting the train ready for the day involves the engineer, brakeman and fireman. On the day of my visit, Daniel Worthy was the engineer on duty, Zach Hebel, Fireman; Logan Jordan, Fireman-in-Training and Larry Poleman was the brakeman.

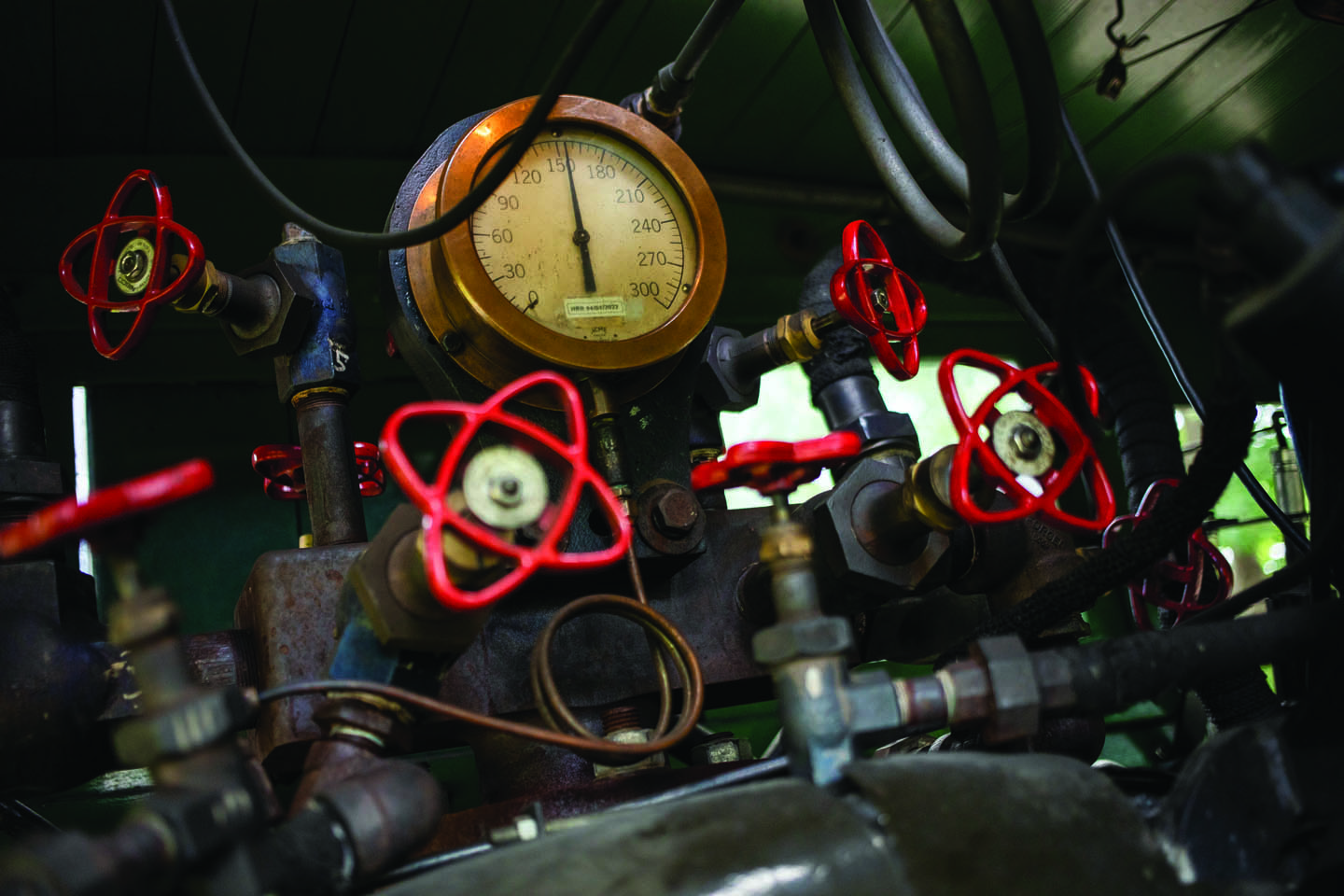

The engineer monitors the train’s speed and ensures that the locomotive runs smoothly. They observe the track for obstructions such as fallen tree branches and use a variety of controls to operate the train, including throttles and air brakes.

The fireman throws coal in the fire and pumps in water to create the steam. Among other maintenance items, the brakeman performs an air brake test before the train runs every morning.

The Rail Shop

Maintenance is a huge priority at Huckleberry Railroad and so is safety. And, it takes many people to maintain the train. The train engine crew includes 11 workers under the direction of Right of Way Supervisor Mick Kimball.

According to Railroad Consultant John Hewlett, all of the mechanical work takes place at the Rail Shop where the steam locomotives are repaired, maintained and restored. The tool room holds an engine lathe, vertical turret lathe machine and a very large air compressor that was donated by Hurley Medical Center. “It is a lot of work and there is a lot to it,” Hewlett reports.” You can’t just go to the store and get parts; they have to be made to specification due to their age.”

A mandated daily mechanical inspection is done by the train crew to make sure everything is in order – bolts are tight, no broken parts. The locomotive is cleaned and the ash pan in the fire box needs to be dropped, ashes cleared out. The coal supply is replenished for the next day’s operation. It’s all part of the daily routine, Hewlett says. They also inspect the railroad track for any defects.

A lot of behind-the-scenes work takes place at the Rail Shop, including replacing the air brakes, maintaining the diesel locomotives, and steam-cleaning the grit and grime. “It’s a dirty job,” says the railroad consultant. A Mott Foundation-funded project was recently completed, an overhaul of Steam Locomotive #152. It was disassembled and rebuilt with new (rebuilt) parts.

The Train Ride

I truly enjoyed chatting with the many dedicated workers who keep the coal-powered steam locomotive on the track! I was fortunate to end the day enjoying a ride, taking in the view from the best seat in the house – the cupola in the caboose.

Photography by Katy Kildee